2020.07.28

Effectivizing the Maintenance Cycle for Pavement Managed by Local Governments

- Inexpensive and High-Perfomance Smart Road Surface Inspection Service Using AI and IoT Launched on August 1st -

Nichireki Co., Ltd.

Nippon Telegraph and Telephone East Corporation

NTT COMWARE CORPORATION

Furthermore, Nichireki officially launched "Smart Road Surface Inspection Service" on August 1st after establishing an inexpensive method for inspection and assessment by using road-surface test cars and combining NTT COMWARE's "Road Defect Inspection System (KT-180052-A)*3" with a location-information service that uses IoT.

*1) Areas in urgent need of measure as local damage is quickly getting worse

*2) "Device and Method for Assisting the Making of Pavement Maintenance and Repair Plans" (patent no. 6738513)

*3) Mechanism for detecting cracks using AI etc., registered with the New Technology Information System of the Ministry of Land, Infrastructure, Transport and Tourism

1. Background and Challenges

There are concerns that road pavement, which were built intensively during the period of rapid economic growth, will become worn out all at once, but the budgets for maintenance and repairs are facing significant cuts. However, the roads managed by local governments are extensive in terms of both number of lanes and total length, making it difficult to repair all damaged areas with overlay*4 or other road surface repair work. The current situation is that they must rely on measures after the fact, such as repairing existing potholes.*5

In addition, the expenses of inspections, which are the entry point for road-surface management, are a heavy burden. At present, there exist a diversity of inspection techniques, but the road-surface test cars*6 that have commonly been used for inspections have stable precision and have won the trust of so many road administrators. Nonetheless, the high inspection costs are a problem, so we have received many requests about more inexpensive inspections using road-surface test cars.

*4) Construction method that puts a layer of asphalt mixture on top of existing road

*5) Holes and depressions caused by the surface course of the pavement coming off

*6) Measuring vehicles with automatic road-surface measuring devices that have passed the functionality test for automatic road-surface measurement devices, conducted annually by the Public Works Research Center.

2. Service Overview

With the aim of solving the abovementioned issues, we developed a new service for inexpensive inspections with road-surface test cars by greatly effectivizing on-site surveys, road-surface measurements, and road-surface image assessment as we utilized AI and IoT technologies for tasks that previously had been performed manually. With this, we managed to cut costs by 60% compared to conventional inspection costs (40% of conventional costs: compared to Nichireki ).

Moreover, we developed new assessment methods and made it a service where the most suitable assessment method can be selected from several methods depending on maintenance and repair policy and budget of the road administrator.

3. Initiative Contents

In preparation of providing this new service, we engaged in the following contents and were able to cut inspection costs by using high-precision road-surface test cars as well as expand the list of services we offer. We are also working on network security measures to ensure that our clients can use our services with peace of mind.

| (1) | Effectivizing On-Site Surveys (Using Electronic Maps) When conducting road-surface surveys in the past, the staff used route maps and other materials borrowed from the road administrator as they made their way to the site and checked the roads to be surveyed, before using road-surface test cars to measure the state of the road surface. Marking the road surface with paint*7 after verifying road length and the locations of beginning and ending points has been conducted by actually driving vehicles so marks can be used when measuring and analyzing. Now, however, we have developed a new system that makes it possible to conduct this kind of work, which previously had to be done on-site, on electronic maps at the office without having to go there. This greatly effectivizes the work and cuts personnel costs. |

*7) Paint on the pavement surface to mark the beginning points, ending points, etc. of the segments to be surveyed

| (2) | Effectivizing Road-Surface Measurement (Using GNSS) By uploading the abovementioned electronic maps that we have developed to a cloud server, it has become possible to check the road to be surveyed from the road-surface test car (Smart Romen Catcher LY Jr.) via the Internet. Moreover, we have added a new GNSS receiver and combined it with NTT DOCOMO's "DOCOMO IoT High-Precision GNSS Location-Information Service," thus making it possible to obtain highly accurate location information with only a few centimeters' margin of error. By linking this location information with the electronic maps on the cloud server in real time, it has become possible to conduct one-person measurements through remote measurement support from the office. In the past, surveys of roads required a navigator as well as a driver, but the work becomes significantly more efficient and the personnel costs lower now that it can be done by one person. |

Situation of the office during measurement and inside the road-surface test car

(Smart Romen Catcher LY Jr.)

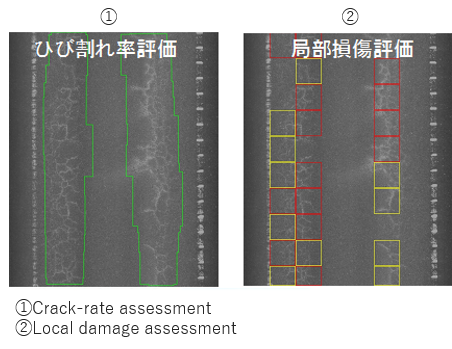

| (3) | Developing New Assessment Methods and Creating Menus We have devised ways to choose assessment methods based on the road administrator's maintenance and repair policy, such as crack-rate*8 assessment for overlays and other repairs or "local damage assessment" for partial mending. "Local damage" assessment is a new assessment method that counts the number of points where cracks intersect (nodal points) in meshes of 50cm x 50cm and ranks them. Areas with a high rank (many nodal points) are deemed that soundness of base course have been deprived *9 and at risk to progess critical damage such as potholes. We use these assessment methods to support the formulation of maintenance and repair plans that are highly realistic in three steps. Step 1: Three-rank assessment by AI into diagnostic classes I–III*10 Step 2: "Crack-rate" assessment based on the Test-Method Manual Step 3: Assessment by AI "local damage" analysis |

|

In Step 1, a three-rank assessment is conducted by AI into the diagnostic classes I–III, which matches the Pavement Inspection Outline. This allows us to see the state of the road surface for the entire road section that is managed. In Step 2, it is possible to rank segments in need of repair (e.g., diagnostic class III [repair stage]) according to urgency of repair by calculating "crack rate" from an analysis based on the conventional Test-Method Manual without the need for remeasurement. In Step 3, "local damage" assessment makes it possible to systematically conduct small-scale mending of areas predicted to require urgent action as local damage is progressing. This is suited for segments where repairs have been postponed for budgetary and other reasons.

In past maintenance and repair plans, there have been big gaps between the costs for segments in need of repair and actual budget sizes, which means they were becoming less realistic. The three-step assessment combines repairs and systematic small-scale mending to help formulate highly realistic maintenance and repair plans.

Practical example of the three steps

The entirety of the managed road is grasped in Step 1, and "crack-rate" analysis is conducted for diagnostic class III, which requires repair, without the need for remeasurement with a road-surface test car. The order of repair works is decided with reference to "crack rate". Areas that are difficult to repair immediately due to budgetary constraints will undergo local damage analysis in Step 3, after which they will be partially mended through systematic cold temperature surface treatment construction method. |

Cold surface treatment construction method

*8) "The number of cracks per 50cm square of road surface is counted, with no cracks being considered as occupying an area of 0㎡, one crack as occupying an area of 0.15㎡, and two or more cracks as occupying an area of 0.25㎡. It is a value (%) derived from a denominator that is the area of the segment surveyed and a numerator that is the integrated value of the abovementioned occupied area calculated based on number of cracks. Japan Road Association, Pavement Survey and Test-Method Manual [1st volume], Maruzen Publishing Co., Ltd., March 2019, pp. [1]-215–[1]-224.

*9) "Study of an Integrated System for Pavement Inspection, Diagnosis, and Measures." 73rd Japan Society of Civil Engineers Annual Meeting (2018).

*10) "Pavement Inspection Outline." October 2016, Road Bureau, Ministry of Land, Infrastructure, Transport and Tourism, p. 11.

| (4) | Effectivizing Road-Surface Image Assessment (Using AI) As regards the assessment of "crack rate", it used to be done by one kilometer per hour even for an experienced analysist since the cracks in road-surface images obtained from the road-surface test car had to be checked by a person. By using an AI that calculate a "crack rate" based on the area of cracks detected, it has become possible to assess about 7km per hour. We have also developed a new AI that specializes in "local damage". This AI uses NTT COMWARE's image-recognition AI Deeptector® and is a technology for detecting where cracks intersect (nodal points) and ranking damage, making it optimal for local damage assessment. The work of local damage assessment is too complex to be analyzed by a person so the use of this AI is the first time it has actually become feasible. |

Analytical image by the crack-rate analysis AI and the local damage analysis AI

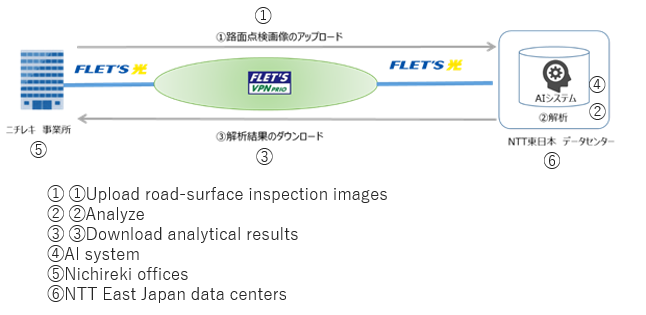

| (5) | Improving Security by Using Closed Network and Data Centers Road-surface images taken by road-surface test cars are sent to and analyzed by NTT COMWARE's AI analysis system that is run at data centers provided by NTT East Japan, transferred via Flet's VPN Prio that is a closed network service also belonging to NTT East Japan. This allows local governments to process the road-surface images in a secure environment. Utilizing the systems in data centers for tasks that previously involved visual analysis by people are now actively incorporated into a new style of business operation that resolves the social issue of being understaffed due to population aging and a declining birth rate as well as avoids human contact as much as possible in this time of coexisting with the coronavirus. |

[Network organization]

4.The Roles of Each Company

(1)Nichireki

Providing smart road-surface inspection service as well as maintenance and repair knowhow

Developing pavement materials and providing materials and construction

Providing formulation of pavement management plans

(2)NTT East Japan

Providing network service for sending images

Providing data centers for storing images and AI analysis

Supporting sales of AI image analysis service

(3)NTT COMWARE

Developing AI image analysis software using Deeptector®

Providing AI image analysis service

5.Inquiries about This Topic

[Inquiries about the smart road-surface inspection service and the road-surface test car (Smart Romen Catcher LY Jr.)]

Naka & Hazama

Pavement Consulting Department

Nichireki Co., Ltd.

Tel: 048-961-6321

https://www.nichireki.co.jp/

[Inquiries about networks and data centers]

Suzuki, Morita, & Niimura

Regional Revitalization Promotion Department

Business Innovation Headquarters

Nippon Telegraph and Telephone East Japan Corporation

Tel: 03-5359-3070

https://www.ntt-east.co.jp/

[Inquiries about image-recognition AI solutions]

Ito & Nakamura

Business Incubation Division

NTT COMWARE CORPORATION

https://www.nttcom.co.jp/

*"Deeptector" is a registered trademark of NTT COMWARE CORPORATION.

*Names of companies, products, etc. in the text may be the trademarks or registered trademarks of the respective companies.