2022.10.25

Analog Meter Reading, AI Judgement, and Automatic Control of Production Equipment Systems used in Factories and Other Productions Sites

- The Launch of a New Version of Image Recognition AI Deeptector® -

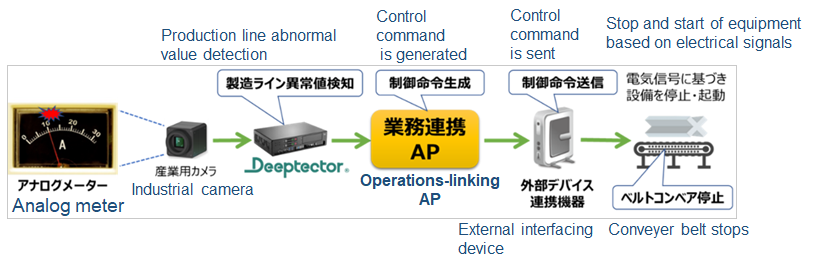

NTT COMWARE CORPORATION (Head office: Minato-ku, Tokyo; President: Masato Kuroiwa; hereinafter NTT COMWARE) added a new judgement model to Image Recognition AI Deeptector® to read analog meter values. This will be available from October 26 along with the Operations-linking Application (AP), which automatically controls operations by sending AI judgement results, including existing judgement models, to production equipment and control systems.

There are many types of existing production equipment and control systems that require human operation or electrical signals from electrical currents or voltage, and directly linking this equipment with AI judgement results has been an issue. Through this application, it is possible to control production equipment by sending and receiving AI-determined results through electrical signals directly as the next action.

Equipment maintenance and inspections have become a huge burden in factories and other productions sites, as problems including maintaining production rate with aging equipment, aging employees, and shortfalls in staffing. We have heard from companies that meters in high places and other dangerous locations are inspected by hand and that it is time consuming to inspect the many analog meters in remote areas spread out over the site. From these comments, NTT COMWARE focused its efforts on replacing work done by humans with image recognition AI to reduce the burden of these tasks. There is a need to automate and digitalize analog meters using IoT and AI, but switching to digital meters incurs procurement costs, as well as costs for peripheral equipment and linkage with systems currently in operation. As a result, there remain many types of equipment that need to be controlled through analog meters and electrical signals, and this is a barrier to introducing AI into actual operations. NTT COMWARE has studied and validated AI's application in actual operations together with companies in the manufacturing and infrastructure equipment industries. Based on this validation, we offer image recognition AI Deeptector, a new service that meets the needs of maintenance and inspection of infrastructure equipment and of factories and other production sites.

Analog Meter Reading Service, reading analog meters and digitizing equipment maintenance and inspection

Reduces the burden of equipment maintenance and inspection by digitalizing values displayed by analog meters with image recognition AI.

Operations-linking Application, a system using AI judgement results in operations directly

Realizes automatic control of existing production equipment and control systems that require human operations, based on AI judgement results. To automate control, applications are needed to mediate between systems that handle AI judgment result data and existing production equipment and control systems with their differing communications protocols. The Operations-linking Application is compatible with Modbus*1, the common de facto standard for automatic control of production equipment. AI judgement results are converted into general-purpose control signals that guide the operations of production equipment, control systems, etc., which then enables automatic operations without manual intervention.

This services offers the following value.

Improvements in Equipment Maintenance and Inspection

Prevents analog meter reading errors and oversight, as well as other human errors, by automating visual inspections. You can also expect an improvement of work efficiency and a reduction in accidents, as it makes it unnecessary for employees to access dangerous or remote places to inspect equipment. It also enables constant inspections instead of regular human inspections. This allows for higher quality equipment maintenance and inspection, including enabling early detection and response of defects.

Proactive Equipment Maintenance

By creating and storing data from analog meter readings and images, it is possible to analyze long-term trends, including monthly and yearly trends and line-by-line and building-by-building trends. The analysis is then reflected in proactive equipment maintenance and repair plans. Early inspection, confirmation, and adjustment of production lines helps to maintain equipment production rates, and leads to further improvements in productivity and more effective use of equipment.

Touch-free Operations

The Operations-linking Application automatically makes decisions based on the status of AI-determined products and equipment and sends converted and compatible electrical signals to production equipment and control systems. This enables control and operation, which enables touch-free operations without manual intervention.

NTT COMWARE will expand as a comprehensive AI service combining sensor data and other data along with image recognition, and will contribute to the promotion of corporate digital transformations through the widespread popularization of AI.

*This service will run a booth at AI EXPO TOKYO 2022 to be held from October 26 to 28, 2022 at Makuhari Messe.

*1 Modbus: a data communications protocol for programable logic controllers (PLC), control equipment produced by a US company Modicon

|

NTT DOCOMO, NTT Com, and NTT COMWARE have rolled out docomo Business, a new brand that combines their corporate businesses as the new NTT DOCOMO Group. The Group will spur innovation in society and industry with a mobile- and cloud-first approach, and will take on the challenge of changing the world together with all of its corporate customers and partners. |